[Power device special] Wolfspeed contributing to the development of SIC power devices

Power semiconductor that holds the key to energy saving

At the beginning

In recent years, the demands of energy saving and CO2 emissions reduction are required, and even more smaller efficiency and improvement of power density in industries, automobiles, communication fields, etc. are required.Power semiconductors, which are often thought to be sober in the semiconductor field, are actually an important device that holds the key to energy -saving in the world.This is because all of this power semiconductor is supplied by this power semiconductor, from compressor motors for home appliances, such as motors, charging equipment, and air conditioners used in electric vehicles (EVs), from compressor motors for home appliances to IoT equipment.Because there is.

In particular, silicon carbides (SIC) and gallium nitride (GAN), which are called wide band gap power semiconductors, are expected to play a major role in this energy -saving and high power density compared to conventional silicon (SI).。

In this article, we will introduce some of the applied fields where the SIC Power Semiconductor is already active, and some of the most promising applied fields, and finally introduce future trends.

1.What is SiC Power Semiconductor in the first place?

It is said that SIC power semiconductors can be more efficient, smaller and lighter than SI Power Semiconductors, but why?As summarized in Figure II, it has excellent material characteristics such as low loss, high -resistant, high -speed switching, and heat resistance.

Although there are some words, simply speaking, SIC is easier to pass through electricity than Si, has a small loss when switching on and off, can withstand large voltage, and can release the generated heat quickly.It will be.Similar characteristics include GAN and gallium oxide (GAO₃), but SICs are ahead of the spread of the market.

Chart ② shows a structural diagram of MOSFET of WolfSpeed.The structure of MOSFET is almost the same for SI and SIC, but the material characteristics shown in Figure (1) can significantly reduce the conversation loss (if the drift layer thickness thickness is 1/10, and the impurities are 1/100, it is an ideal case.1 /1000).

WolfSpeed's Mosfet 2nd and 3rd generation processes are both called player types, and since they have the simplest structure, they are characterized by simplification, low cost, and high reliability of manufacturing processes.The third generation of the latest process (GEN3) has achieved the industry's top class low -class loss (on -resistance).

The feature of GEN3 is that the temperature dependence of low voltage drive ( + 15VGate Drive) and on -resistance rising (~ 1).3XINCREASE RDSON OVER TEMP), in -vehicle compatible quality, etc.This latest process offers 650V, 900V, 1000V, 1200V, and 1700V-resistant Sic-Mosfet.

2.Applied fields where the spread of SIC power semiconductors is already in maturity

Applied applications targeted by WolfSpeed's Sic-Mosfet series are diverse, such as server power supply, industrial UPS, and solar power generation.

From this, we will introduce three applications that SICs have already spread and maturity.First, there are two circuits: PFC (power rate improvement) circuit such as server, telecom, general -purpose (Hanyo) power supply, and MPPT (maximum power follow -up control) of solar power generation.

These circuits are often used with SIC shot key barrier diodes.The reason is that the SIC shot key barrier diode has a zero reverse recovery characteristics, and the switching loss when the current switches from on to off is almost zero.

The third example is the "titanium" of the highest grade of the standard 80 puls regarding the power conversion efficiency..It is a 2kw tootem pole PFC circuit.Sic-MOSFET (C3M0060065J / 650V / 36A / TO-263) is switched at 64kHz for switching, and the SI's first lycarer diode is used for rectification to achieve both high efficiency and low cost.97 of the highest efficiency demo board using SI-MOSFET.2 % 1.5 % higher, 98.It has a high efficiency of 7 %, and THD (Total Harmonic Distortion overall high -wave distortion) is 3.Achieve within 5 %.

3.Why SIC Power Semiconductors is used in EV

Major car manufacturers around the world have expressed their intention to promote EVs one after another.GM (GENERAL MOTORS) plans to electrify all new models in the early 30s in the early 30s.Volvo says that all -sales vehicles will only be EVs by 30 years, and BMW and Volkswagen will increase the EV sales ratio in Europe to 50 % and 70 % by the same year.

However, EVs face two major issues, price and cruising range.The use of SIC power semiconductors, which enhances the switching frequency and improves heat dissipation performance, is one approach that solves these issues smaller / lighter the in -vehicle components (traction Inverters and on -board chargers).A European car manufacturer also states that "these benefits can reduce traction inverters power loss by more than 70 % and reduce the size of the vehicle battery charger by 25 %."

Next, we will introduce the newly developed products of the cutting -edge SIC power module that are optimal for large power converters such as EVs.

Chart ③ shows the characteristics of the WolfSpeed's unique power module, XM3, which makes full use of the high -temperature movements and high -speed switches of SIC Power Devices.Modular arrangement, expandability, easy bass bar connection, low inductance, and miniaturization of full bridge and three -phase bridge circuits.Three types of products are prepared so that the inverter output can be optimized for 200, 250, and 300 kW.

Chart ④ shows a comparison of the size with other industry standard power modules with the same performance as the power module XM3.Comparing the industry standard 62 mm and half bridge power modules and the unique XM3 power module of WolfSpeed, the size is 50 % smaller and the parasitic inductance can be reduced by 50 %.

Chart ⑤ is a 300kW inverter design example using the world's smallest SIC Power Module XM3.Compared to an inverter with the same output capacity using the silicon IGBT power module, the inverter weight is less than half.The use of low inductance and laminated bass bar, which is a feature of XM3, has also realized a snb -less, and contributes to further miniaturization and low cost.

4.6 for V2X.6kw double -direction AC / DC

EVs and plug -in hybrid vehicles are equipped with a power converter called an on -board charger (OBC) to charge the built -in large -capacity lithium -ion battery.It is a mechanism to charge the vehicle battery with a DC voltage converted to a predetermined voltage from an AC200V such as AC200V.In addition, it has a function that can be applied to a system that supplies power from in -vehicle batteries to power systems called V2G (VEHICLE TO Grid).

Chart ⑥ ⑥ in the industry's top class high power density 3.V2G compatible 6 achieved 3kw / L.The circuit configuration of the 6kw bidirectional AC / DC converter is shown.

This design design is to store PFC inductors and CLLC components in the heat sink in the box -shaped shape to make it smaller..3kw / L has achieved high power density.

The CCM TOTEM POLE PFC circuit uses C3M0060065K (TO-247-4) in parallel in parallel. The operation switching frequency is 67kHz, the DC-LINK voltage is fixed to the 380-425V range, and 650V pressure-resistant MOSFET can be used.We are trying to reduce costs.Bi-Directional CLLC uses one C3M0060065K as a switch to control the interior input / output DC voltage with a variable frequency of 150 to 300 kHz.

Chart ⑦ 6 in 6.6kw shows the total measurement result of the comprehensive efficiency of two -way AC / DC conversion.The maximum efficiency of the charging mode was 96.8 %, and the discharge mode was 97 %, which was very efficient.

summary

SIC Power Devices are already used as industrial equipment power supply, solar power conditioner, and EV charger (onboard charger OBC and quick charger).It is expected that the use of SIC Power Semiconductors to traction Inverters will become more active in the background of the rapid increase in EVs.

According to the investigation company YOLE DéveloppeMent, the power device market is expected to be $ 23 billion in 2025, $ 23 billion in 2025.In response, SIC and GAN compound semiconductors are expected to grow from $ 977 million to $ 4 billion at 10 times the power device market.

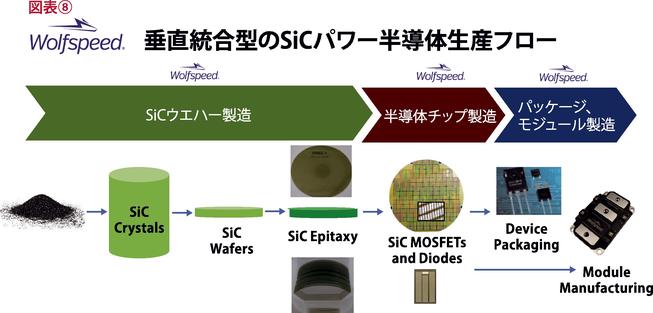

Wolfspeed has been playing a role as a global leader of a 30 -year -old wide band gap semiconductor, and as shown in Chart II, SIC Wae (manufactured from Ingot, Subtrette to Epi Era) and SIC Power Vice.It is a vertical integrated power semiconductor manufacturer that develops, manufactures and sells.

Wolfspeed promotes further improvements in SIC power semiconductors and reducing costs due to aggressive investment, dramatically expanding the application range of SIC power semiconductors, and SIC Power Semiconductor SIC Power Semiconductor.Replacement is a social mission.

WolfSpeed Lowe CEO says, "SIC Power Semiconductors are expected to be popular in five years, like the EV, and are now a dramatic technical turning point that triggered them."To meet the expected increase in demand, Wolfspeed is under construction of the world's largest SIC fab and will start production in 2010.The newly established SIC Fab, newly established in Mercy, New York, is a manufacturing plant dedicated to the world's first 200 mm -motto wafer, and is expected to be significantly reduced costs than the conventional 150 mm wafer line.

With such a SIC Power Device Revolution, if the cost reduction of SIC continues in the future, the SIC will compete in the market with SI-IGBT by 30 years, and it is expected to be adopted in a wide range of EV models.When that happens, various markets come into view.In addition to industrial inverters, substantial equipment, and general industrial equipment, white goods may be eligible.In the near future, EVs may be just one corner of the expansion of the SIC market.

Despite the omission on the paper, the development of emerging products, which was unreasonable in Si, is also progressing due to the advantage of SIC material characteristics, and the expansion of the application range is highly expected.

Useful information on YouTube is being released.Search by "SIC Power Semiconductor Promotion Department".

![[EV's simple question ③] What is good for KWH, which represents the performance of the battery?What is the difference from AH?-WEB motor magazine](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/b2506c4670f9f2cb45ffa076613c6b7d_0.jpeg)

![[How cool is the 10,000 yen range?] 1st: The performance of the "robot vacuum cleaner with water wiping function (19800 yen)" like Rumba is ...](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/25/5251bb14105c2bfd254c68a1386b7047_0.jpeg)