"OPC UA" that allows machinery to talk to each other, accelerates the intelligentization of the manufacturing site

On June 30, 2021, a study session for members of the DX Information Collection Service, one of the members of IOTNEWS, was held.In this paper, we will introduce the session of Omron Oka Co., Ltd.

Mr. Oka is planning a product of PLC and industrial controllers in Omron, while also chairman of the Marketing Section of the Japan OPC Council, promoting the spread of OPC UA in Japan.

Mr. Oka gave a lecture on the changes that occurred at the manufacturing site from the two positions and the intelligent of the manufacturing site utilizing OPC UA.

table of contents

Three changes that are occurring at the manufacturing site

First, Oka mentioned the issues at the manufacturing site.

It is said that three major changes have occurred at the manufacturing site.

Changes in the place to make

The first is the change in the place to make.It is said that manufacturing is becoming globalized, and the number of companies who want to produce as much as possible near local production for local consumption and consumption is increasing.

Changes in how to make

The second is the change in how to make it.Electrical products, such as smartphones, are becoming smaller and high performance.In addition, the material used for manufacturing is changing as the movement of reducing plastic for environmental response is progressing.

In order to respond to such changes in products, the way of making must be changed.

Changes in human making

The third is the change in the human being made.In Japan, the manufacturing population has decreased, and the number of skilled workers is decreasing.On the other hand, many Japanese companies have been producing in Asia due to low labor costs, but labor costs in Asia have soared.

Along with the place to make, it is necessary to review who will make it.

The manufacturing industry is now required to respond to new changes in the manufacturing site.

Changes in the market environment can be seen from the number of recalls in the automotive industry.

According to the data published by the Ministry of Land, Infrastructure, Transport and Tourism, the number and number of recalls have risen in the 30 years of Heisei.

Mr. Oka said, "By using common parts in various models to improve efficiency, the target number increases in one recall, and many electrical parts are installed in cars.It is possible that production is difficult and it is likely that defects are likely to occur. "

Intelligence of manufacturing sites corresponding to changes

In order to solve the issues at the manufacturing site as described above, it is necessary to convert the manufacturing site.

Intelligence of manufacturing sites means improving manufacturing sites by collecting and using data at manufacturing sites.Expectations for using AI, IoT, and robotics are increasing for problem solving.

Already, we are studying human coordination robots for collaborating on the same production line as workers, and flexible production lines that realize the optimal production method in line with multiple small quantities production.OMRON offers a cooperative robot and a mobile robot that can carry luggage.

In order to expand the range of data utilization at manufacturing sites, it is necessary to cooperate with IT solutions, aiming to further increase the range of data utilization at manufacturing sites.

However, the manufacturing site and IT have advanced in different cultures, and there is a boundary.How should we connect the manufacturing site and IT to eliminate the boundaries for data use?The important thing here is the OPC UA, the point in this lecture.

What is "OPC UA", which aims for the interoperable operation standards of the industry?

OPC UA is a communication protocol that aims to become an interoperable operation standard in the industry.OPC Foundation, a global organization, has been promoting its popularity since around 2008.

The realization of the world that OPC UA aims for, allowing you to use industrial equipment and machinery with the ease of using printers and headsets at home.

Printer and headset can be used without being aware of the manufacturer by connecting to a PC or smartphone with USB or Bluetooth.This is a state of interaction.As mutual operation can be performed, each manufacturer will differentiate itself based on product value such as performance and price.

It is a world that OPC UA is aiming for the idea of enabling interactions that are possible with such home appliances in the industry.

In 2015, OPC UA, Industrie4.As a recommended standard for realizing 0, "RAMI4.0 (The Reference Architectual Model Industrie4.0) It was published in].From here, OPC UA has become noticed around the world.In addition to being adopted in China's "China Manufacturing 2025", collaboration with more than 50 industry groups is progressing.

One of the characteristics of OPC UA is that user companies are participating.Cosmetics manufacturers, Loreal and Volkswagen, a car manufacturer, are becoming a member of the OPC Foundation and trying to spread it.

In addition, the participation of IT companies is increasing.It is said that Microsoft, Amazon, Google, etc. are participating and promoting OPC UA.

OPC UA visions to change information in the industry into value.In order to fulfill that vision, we believe that three things are "connected", "tap", and "safely".

"Connect"

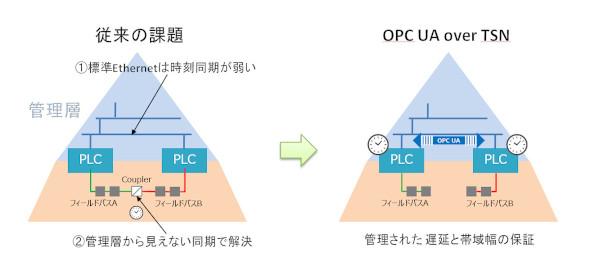

The major change is that the industrial Ethernet entered the factory in 1994 in terms of connecting.Later, OPC Classic and OPC UA appeared, and the movement of connecting the Ethernet to the axis has come out.

Until the OPC was formed, it was necessary to connect to each manufacturer in order to connect the upper visualized software such as HMI and the factory machine.

In the first generation of OPC, the OPC server is installed between the visualized software and the machine, enabling multi -vendor connections for the higher -level visualization software without worrying about the manufacturer.

OPC UA, the second generation of OPC, does not depend on the OS and has a technology that supports international standards.It is possible to exchange structured data and information, and supports security.

"Try"

Until the OPC UA came out, raw data was replaced.The data of the string with different parameters is sent for each vendor, so it was only transmitted to those who understand the meaning, and it was effortless to make it into a documentation.

In order to solve this problem, OPC UA responds to multi -vendors so that the meaning is transmitted.It is an image that you can talk between robots.

An important technology to convey the meaning is the information model.This expresses the meaning of the meaning.

By defining information such as sensors as models and connecting them to the interface, you can convey what is right now.

By performing such a device to convey with various machines, the structure and meaning are transmitted, and information can be used at the manufacturing site.

"safely"

OPC UA supports security.

We perform application authentication, user authentication, and user approval.Only predetermined things are attached, and the connections are encrypted or not tampered.

OPC UA application range

OPC UA has already been applied in industrial machinery.In the injection molding machine, production conditions, operation status, production results, etc. are standardized as information models, so it is now possible to interact with MES (production execution system) without relying on manufacturers.

By using OPC UA, the manufacturing site and IT are connected without boundaries, so that data can be used more.

In addition to communication between IT/OT, OPC UA is trying to expand the applied area from sensors to cloud, such as communication between OTs and connecting to the cloud.

Intelligence examples

Oka introduced seven examples, including examples of Omron factories in a study session.All cases are produced by successfully connecting the boundary between IT and OT.

OMRON considers the top connection with IT to be important, and the latest controller is equipped with OPC UA as standard.

In addition, it can be connected directly to the database to collect traceability data, or it can be directly connected to the cloud.

Here are two of the seven cases.

Quantification of craftsmanship

The Omron Kusatsu Plant produces a mold, and there is a machining center that creates a discharge electrode for producing the mold.

A machining center is a processing machine that performs multiple processing in a row while automatically replaces tools by computer control by a pre -set program.

However, in fact, it is not only necessary to make a setting, but it is necessary for a skilled person to observe the processing and set according to the object and the surrounding environment.

There is an issue that skills cannot be passed on from skilled people to successors, and data utilization has started.

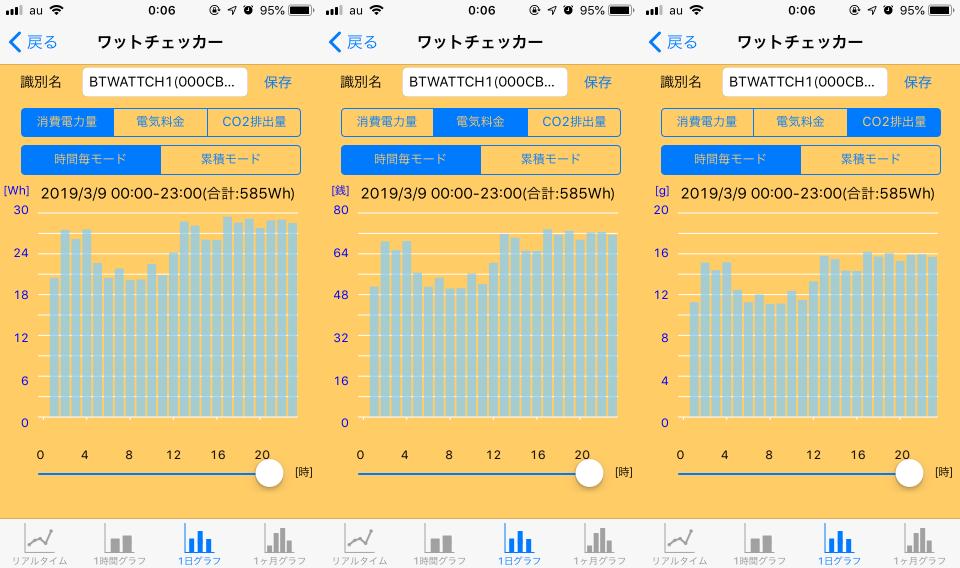

The vibration sensor has been installed near the processing material, collecting data, accumulating and analyzing, making it possible to create a unique algorithm, and controls the cutting resistance.

This has made it possible to reduce the processing time by 40 % beyond the skills of skilled people, as well as the skills of skilled people.

It is important to collect accurate data, and you need sensing, analysis, and control know -how.This is the know -how accumulated because Omron has been involved in automation of manufacturing sites.

Smarting social infrastructure

In addition to manufacturing sites, examples of intelligentization using OPC UA are expanding.

This is a case where a shopping center has controlled a commercial smart trash can with PLC.

It is said that a smart trash can have been introduced for the purpose of increasing the recycling rate and the purpose of reducing the operation cost.

It seems that the trash cans were prepared for general garbage and recycle garbage, and the collection costs were divided.When the garbage was discarded, the weight was automatically weighed, and a mechanism was created to automatically charge the collection costs according to the weight.General garbage collection costs are set higher than recycled garbage collection costs.

From a shopping center, if a lot of garbage is thrown away in the trash can for general garbage, more costs will cost, so you will be able to operate as much recycled garbage as possible.

From the collector's perspective, it is possible to check when the trash can be full, so you can optimize the operation.

Other cases introduced in the lecture

In a lecture, Oka also introduced the following five intelligent cases in addition to the above examples.

(I will omit it in this article.)

Direction of future data utilization

Oka believes that data utilization will spread in two directions in the future.

One is that the range and level of information utilization are expanding.

The range of information utilization will extend from the range of equipment and production lines to the entire factory, some factories, and even companies.

Already, there is a movement to optimize the entire supply chain to perform pharmaceutical serialization.In the automotive industry, in order to ensure the safety of automatic driving cars, we are trying to implement manufacturing traceability, including parts factories.

The level of information utilization is currently performing data collection and visualization, but in the future, it will proceed to the level of control, such as remote, anticipation, and further automation.

Another direction is that the range of information utilization is expanded not only in real but also to virtual.

When a problem occurs in a factory, the use of data in virtual will provide you remotely support and solve the problem without any experts.

DX information collection service provided by IOTNEWS

IoTnews provides DX information collection services that include such study sessions.It is a service that supports "collection of trend information" and "acquisition of actual know -how", which is essential for DX.

This article is a study session digest article, but in the actual study session, you can hear more stories from experts who are in charge of IoT and AI sites and ask questions directly.In addition to study sessions, it offers trend reports created by Art Gean Co., Ltd. consultants and provides a DX hotline that allows casual consultation based on email.

Please check the link below for details.

DX情報収集サービスの詳細はコチラから小畑俊介After graduating from university, he worked for a manufacturer.He is involved in the launch of a new line as a production technical position and a Kaizen business in the factory.He joined the company in July 2019 and is exploring the possibility of IoT centered on the manufacturing industry.

![[EV's simple question ③] What is good for KWH, which represents the performance of the battery?What is the difference from AH?-WEB motor magazine](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/b2506c4670f9f2cb45ffa076613c6b7d_0.jpeg)

![[How cool is the 10,000 yen range?] 1st: The performance of the "robot vacuum cleaner with water wiping function (19800 yen)" like Rumba is ...](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/25/5251bb14105c2bfd254c68a1386b7047_0.jpeg)